MONIPA

About Monipa

Monipa focuses on simplified bioprocess monitoring: our measurement system is based on mid-infrared (MIR) spectroscopy and monitors multiple parameters inline at the same time. Spectroscopy is a powerful technique that allows the analysis of various relevant parameters. Therefore, Monipa is beneficial in both upstream bioprocessing; in metabolite monitoring and control, as well as in downstream bioprocessing to aid in contaminant detection or monitoring of target proteins and excipients.

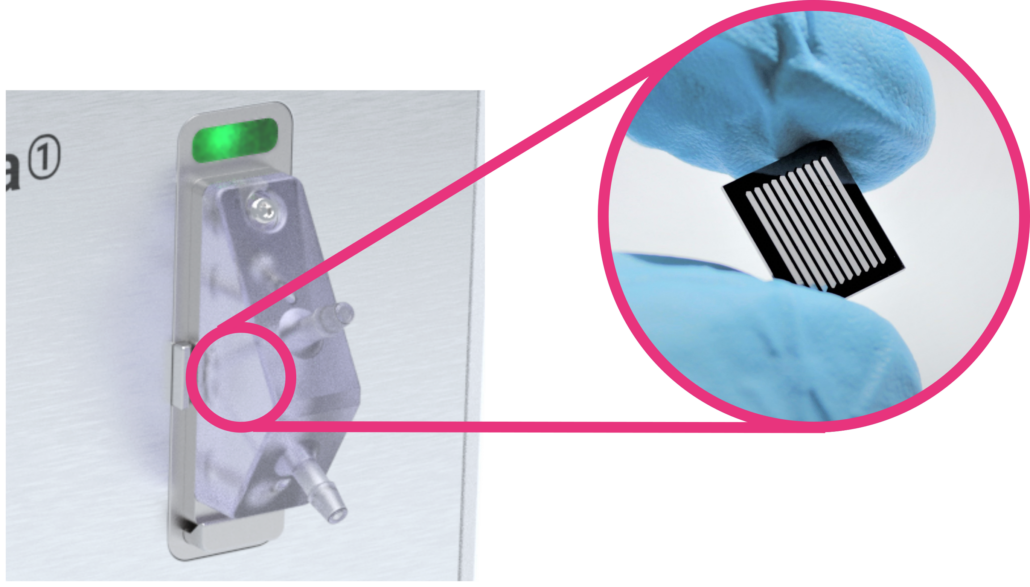

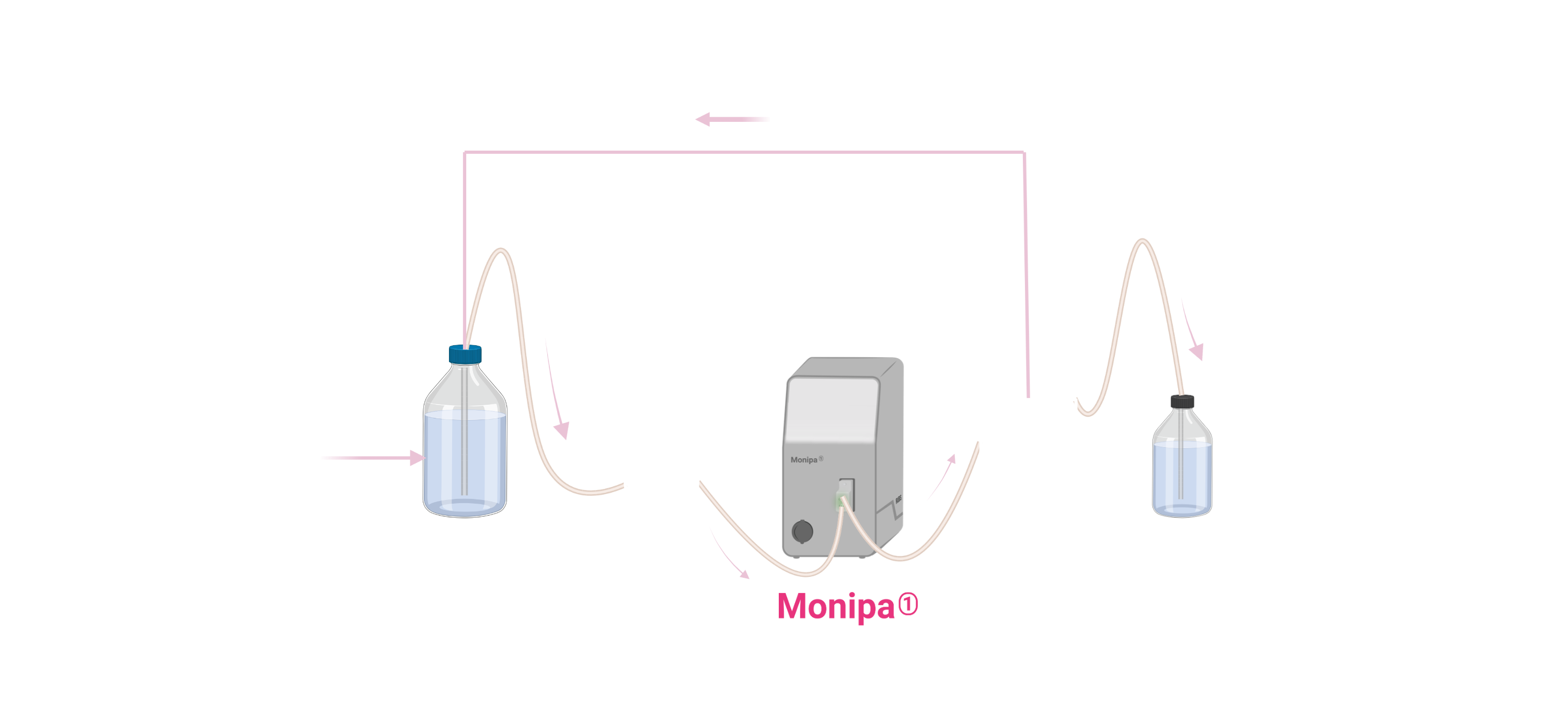

Our Single-Use Flow Cell

The single-use flow cell is one of the core elements of Monipa. An easy screw mechanism enables a stable fixation of the flow cell. At the same time it allows the replacement of the flow cell after each monitored process, reducing contamination risk. The flow cell contains our single-use silicon ATR crystal, enabling a disposable unit. By connecting the flow cell via loop to e.g. the bioreactor or a chromatography column, different parameters can be monitored online or inline. Stable measurement conditions are achieved due to the external flow cell, that is mounted e.g. outside of the bioreactor. This prevents disturbances of the measurements by gas bubbles or by the stirrer which both can occur inside the bioreactor.

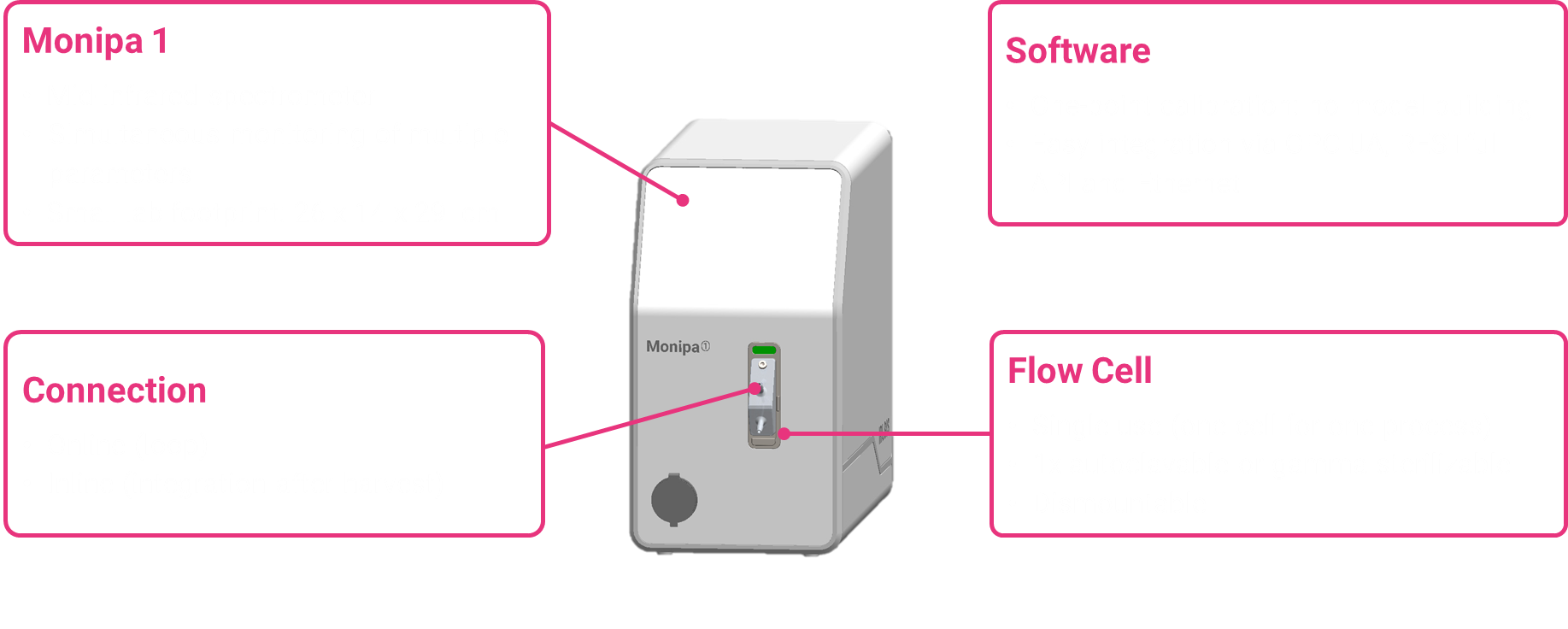

MONIPA OVERVIEW

No Calibration Model Building

Calibration model building is an important step for spectroscopic devices. The spectra depends on the molecules in the measured samples. Following this, also different cell lines, cell culture media, metabolite or nutrient concentration leads to changes in the spectra. Calibration models are built by correlating the spectroscopic measurements to the reference method.

IRUBIS’ inline and online monitoring solution Monipa offers an innovative approach to solve the time extensive and costly calibration model building. IRUBIS one point calibration is based on a relative measurement. Only the known start-value of the parameter need to be included. Consequently the measurement of reference processes for calibration model building are not necessary.

Inline Monitoring in Downstream Processing

Monipa adresses a variety of different applications in downstream processing, especially taking into account its fast acquisition time of less than 1 minute per data point. Such applications include protein and excipient concentration monitoring. Download our e-book or click application notes to learn more!

Benefits in Downstream Processing

How does Monipa work in Downstream Processing?

Monipa is successfully used in the determination of protein concentration as well as excipient concentrations with real-time and inline measurements at various stages of downstream processing. It can be used during the Ultra-/Diafiltration and integrated with equipments frequently used for protein purification, such as ÄKTA Pure. Get in touch with us to elevate your downstream applications with higher yields and intelligent insights!

Monipa in Ultrafiltration and Diafiltration

In this case, the publication shows the inline measurement of the concentration of excipients and proteins comparing mid-infrared spectroscopy compared to an OD280 assay. The publication shows accuarcy of the measurement system with a calculated coefficient of determination of R² = 0.995.

Milewska et al. Eng Life Sci. 2023;23:e2200050

Protein Secondary Structure

Mid-infrared spectroscopy enables differentiation of protein secondary structure such as alpha helices, beta sheets and random coil structures. In particular, a distinct feature of protein aggregation is the increase of crossed β-sheet structures. Hence, IR Spectroscopy is a useful tool to analyze secondary structures of proteins, and their aggregation in complex samples.

Wang et al (2015), Anal Bioanal Chem 407: 4015-21

Ángela I. López-Lorente , I, A & Mizaikoff, B (2016), Anal Bioanal Chem 408: 2875–89

Monitoring and Control in Bioreactors

The use of MIR spectroscopy for inline measurement of glucose and lactate in mammalian cell cultures has already been demonstrated in recent studies (Sandor et al., 2013; Wu et al., 2015). To point out, drawbacks are high equipment costs and low robustness of the ATR probes. IRUBIS has managed to solve many of these teething issues with our Monipa system.

Benefits in Upstream Processing

- 24/7 inline monitoring of metabolites and nutrients as well as glucose control

- Real-time data and glucose control (closed loop)

- Single-use flow cell decreases contamination risk

- Parallel monitoring of multiple parameters

- Increased robustness compared to other spectroscopic methods

- Reduced calibration time by one-point calibration

- Suitable to to a variety of different cell types; from CHO mammalian cells, to microorganisms such as bacteria

Integration into bioreactors

Monipa can be integrated inline into the harvest stream in perfusion processes as well as online into fed-batch processes. In another case, the technology has been used in fixed-bed bioreactors at biopharma companies. Leave us a message if you are interested in learning how to integrate Monipa into your specific process or in a version to monitor multiple processes in parallel!

Why Partner with IRUBIS?

Sensitive and robust measurements that do not require additional, time-consuming calibration are a much-desired need in biopharmaceutical manufacturing. Together in IRUBIS, we fill this gap with our novel technology, Monipa. We work closely with you to ensure a seamless integration of Monipa into your bioprocesses. Our team offers the best to provide you constant guidance and support to assure everything runs smoothly. Partner with us and improve your bioprocess!

“We developed a solution for inline quality monitoring in the downstream process using a MIR Spectroscopy device, Monipa, from IRUBIS. The past 10 years have shown spectroscopic techniques to be powerful analytical tools for process development and biologics manufacturing.”

“CPI recognises that the biopharma industry requires the development of novel process analytical technologies (PAT) that can be deployed in and on-line to determine a variety of critical quality attributes and critical process parameters. The Monipa, developed by IRUBIS GmbH, is an example of novel PAT that can be deployed in both upstream and downstream biological applications.”

“Increase product knowledge and process robustness through data connectivity and integrity – this is IRUBIS vision. We are proud to support IRUBIS excellent team with implementation of Monipa’s OPC UA interface to the PAT platform, SIMATIC SIPAT, in LivingLab Vienna.”

S.T. Japan distributes Monipa in Japan. The company is a leading manufacturer and distributor of high-quality accessories for sample preparation and spectra databases for analytical laboratories in industry, science and education.

Join Our Newsletter!

About Monipa

Monipa focuses on simplified bioprocess monitoring: our measurement system is based on mid-infrared (MIR) spectroscopy and monitors multiple bioprocesses inline at the same time. Spectroscopy is a powerful technique that allows the analysis of various relevant parameters. Therefore Monipa is beneficial in both upstream bioprocessing; in metabolite monitoring and control, as well as in downstream bioprocessing to aid in contaminant detection or monitoring of target proteins and excipients.

Our Single-Use Flow Cell

The single-use flow cell is one of the core elements of Monipa. An easy screw mechanism enables a stable fixation of the flow cell. At the same time it allows the replacement of the flow cell after each monitored process, reducing contamination risk. The flow cell contains our single-use silicon ATR crystal, enabling a disposable unit. By connecting the flow cell via loop to e.g. the bioreactor or a chromatography column, different parameters can be monitored online or inline. Stable measurement conditions are achieved due to the external flow cell, that is mounted e.g. outside of the bioreactor. This prevents disturbances of the measurements by gas bubbles or by the stirrer which both can occur inside the bioreactor.

No Calibration Model Building

Calibration model building is an important step for spectroscopic devices. The spectra depends on the molecules in the measured samples. Following this, also different cell lines, cell culture media, metabolite or nutrient concentration leads to changes in the spectra. Calibration models are built by correlating the spectroscopic measurements to the reference method.

IRUBIS’ inline and online monitoring solution Monipa offers an innovative approach to solve the time extensive and costly calibration model building. IRUBIS one point calibration is based on a relative measurement. Only the known start-value of the parameter need to be included. Consequently the measurement of reference processes for calibration model building are not necessary.

Inline Monitoring in Downstream Processing

Monipa adresses a variety of different applications in downstream processing, especially taking into account its fast acquisition time of less than 1 minute per data point. Such applications include protein and excipient concentration monitoring.

Benefits in Downstream Processing

Monipa in Ultrafiltration and Diafiltration

In this case, the publication shows the inline measurement of the concentration of excipients and proteins comparing mid-infrared spectroscopy compared to an OD280 assay. The publication shows accuarcy of the measurement system with a calculated coefficient of determination of R² = 0.995.

Milewska et al. Eng Life Sci. 2023;23:e2200050

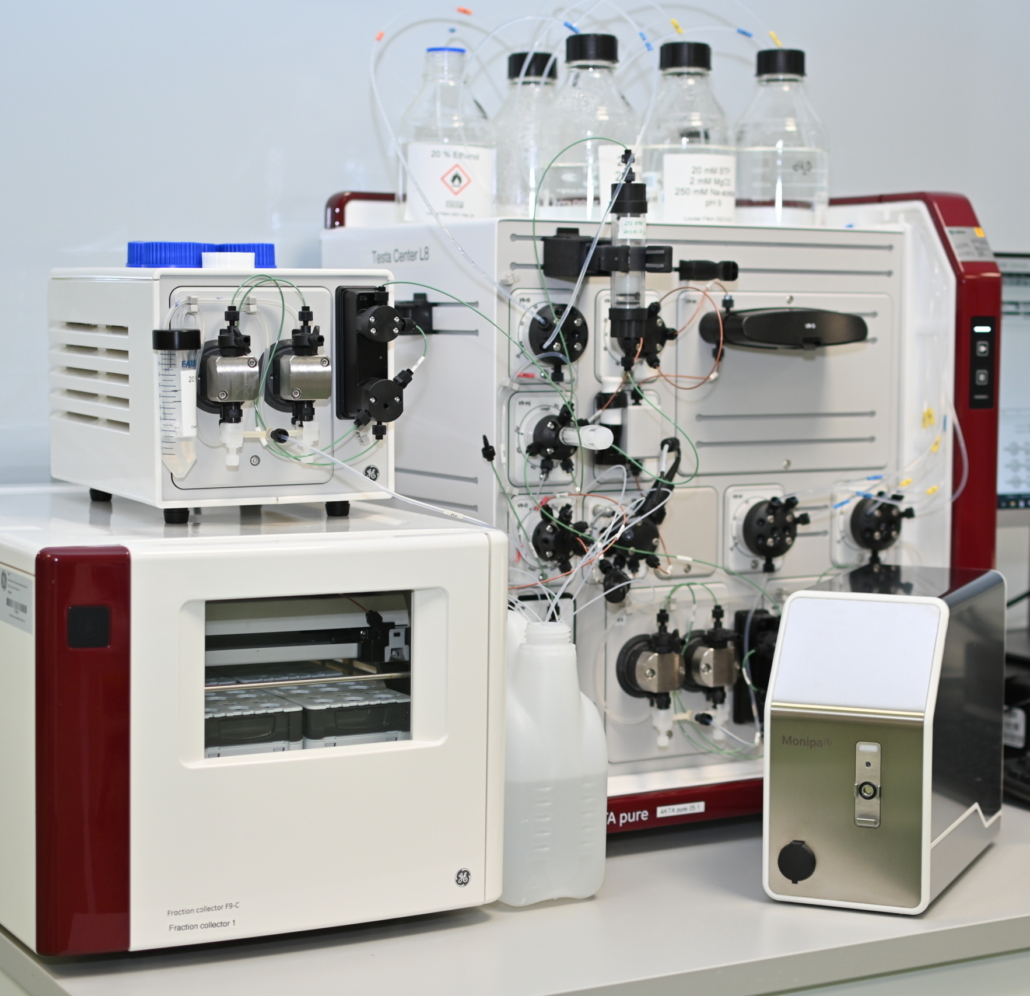

How does Monipa work in Downstream Processing?

Monipa is successfully used in the determination of protein concentration as well as excipient concentrations with real-time and inline measurements at various stages of downstream processing. It can be used during the Ultra-/Diafiltration and integrated with equipments frequently used for protein purification, such as ÄKTA Pure. Get in touch with us to elevate your downstream applications with higher yields and intelligent insights!

MONIPA INTEGRATION INTO UF/DF

MONIPA INTEGRATION WITH ÄKTAPURE

Protein Secondary Structure

Mid-infrared spectroscopy enables differentiation of protein secondary structure such as alpha helices, beta sheets and random coil structures. In particular, a distinct feature of protein aggregation is the increase of crossed β-sheet structures. Hence, IR Spectroscopy is a useful tool to analyze secondary structures of proteins, and their aggregation in complex samples.

Wang et al (2015), Anal Bioanal Chem 407: 4015-21

Ángela I. López-Lorente , I, A & Mizaikoff, B (2016), Anal Bioanal Chem 408: 2875–89

Monitoring and Control in Bioreactors

The use of MIR spectroscopy for inline measurement of glucose and lactate in mammalian cell cultures has already been demonstrated in recent studies (Sandor et al., 2013; Wu et al., 2015). To point out, drawbacks are high equipment costs and low robustness of the ATR probes. IRUBIS has managed to solve many of these teething issues with our Monipa system.

Benefits in Upstream Processing

- 24/7 inline monitoring of metabolites and nutrients as well as glucose control

- Real-time data and glucose control (closed loop)

- Single-use flow cell decreases contamination risk

- Parallel monitoring of multiple parameters

- Increased robustness compared to other spectroscopic methods

- Reduced calibration time by one-point calibration

- Suitable to to a variety of different cell types; from CHO mammalian cells, to microorganisms such as bacteria

Integration into bioreactors

Monipa is compatible with different kind of bioreactors and processes. It can be integrated inline into the harvest stream in perfusion processes. In addition it is suitable as online monitoring system in fed-batch processes. In another case, the technology has been used in fixed-bed bioreactors at biopharma companies. If you interested how to integrate Monipa into your specific process or in a version to monitor multiple processes in parallel, please leave us a message.

MONIPA IN PERFUSION PROCESS

MONIPA IN FED-BATCH PROCESSES

Partner with Monipa: Improve your Bioprocess

“We developed a solution for inline quality monitoring in the downstream process using a MIR Spectroscopy device, Monipa, from IRUBIS. The past 10 years have shown spectroscopic techniques to be powerful analytical tools for process development and biologics manufacturing.”

“Increase product knowledge and process robustness through data connectivity and integrity – this is IRUBIS vision. We are proud to support IRUBIS excellent team with implementation of Monipa’s OPC UA interface to the PAT platform, SIMATIC SIPAT, in LivingLab Vienna.”

S.T. Japan distributes Monipa in Japan. The company is a leading manufacturer and distributor of high-quality accessories for sample preparation and spectra databases for analytical laboratories in industry, science and education.

Join Our Newsletter!

Get in Touch!

Ariana

Technical Sales Engineer

Alan

Technical Sales Engineer