Overcoming Challenges in mAb

Process Development

Why inline downstream monitoring matters?

Integration of Monipa into mAb Downstream Processing

Inline UF/DF monitoring with Monipa

UF/DF is one of the most effective separation techniques and a critical step in downstream processing for precisely achieving the target product composition. The process relies on a permeable membrane to selectively separate components as a specific volume of formulation buffer is exchanged. It can be divided into key stages:

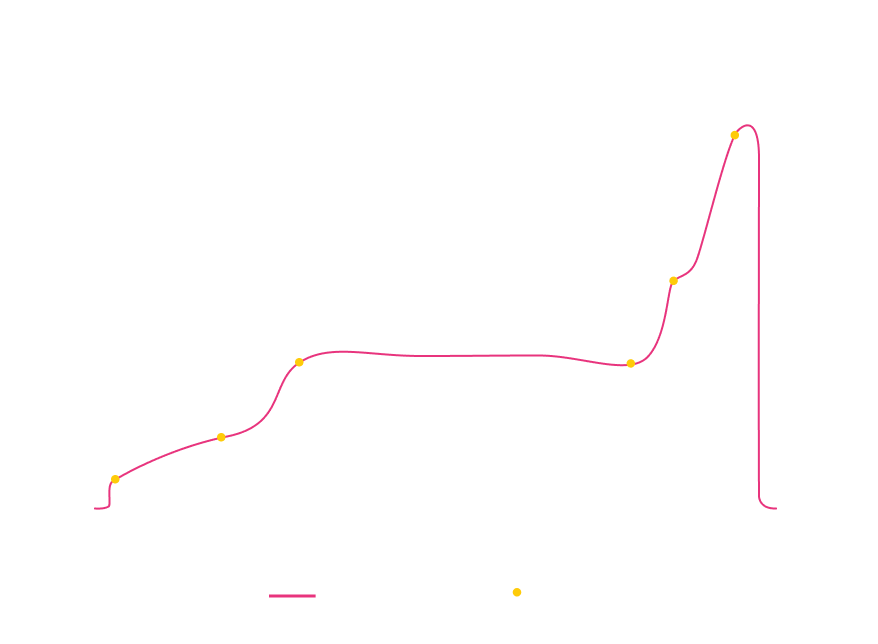

Ultrafiltration 1

Accurate timing of UF1 improves consistency and reduces process variability.

Diafiltration

Moving beyond fixed DF volumes with real-time monitoring optimizes buffer usage.

Ultrafiltration 2

Preventing deviations at this stage helps avoid reprocessing or, in the worst case, batch loss.

Ideal UF/DF Scenario

Related Assets

Replacing offline process control with instant inline data offered by Process Analytical Technology ensures tight control over UF/DF. Monipa is successfully used to determine protein and various excipient concentrations with inline measurements during UF/DF in mAb downstream processing. Get in touch with us to explore tailored applications to your processes!

Case Study

Simultaneous Real-Time Monitoring of Protein and Sugars in UF/DF Process

Authors: AGC Biologics, IRUBIS

Application Note (2023)

Real-time infrared monitoring of an ultra-/diafiltration process

Authors: Adrianna Milewska, Clemens Minnich, Simon Kern